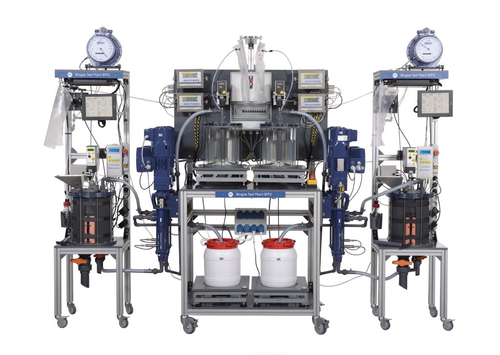

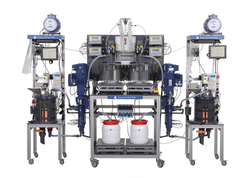

BTP2 - with feeding and discharge pumps

Use of different types of pumps and scales for accurate feeding

The individual BTP modules can also be equipped with tube or eccentric screw pumps.

Additionally, the system is equipped with scales for an exact feeding result.

The pump modules and the scale modules are controlled by the SENSOcontrol units.

Additional Features Tube Pumps

- Tube pumps for feeding, discharge and pH-value control

- High quality tube pumps

- Available tube inner diameter: 0.8 mm;1.6 mm; 3.2 mm; 4.8 mm; 6.3 mm and 8 mm

- Minimum flow rate 0.5 ml/min and max. flow rate 840 ml/min with different tube inner diameters and revolutions per minute

- Control of tube pumps via SENSOcontrol

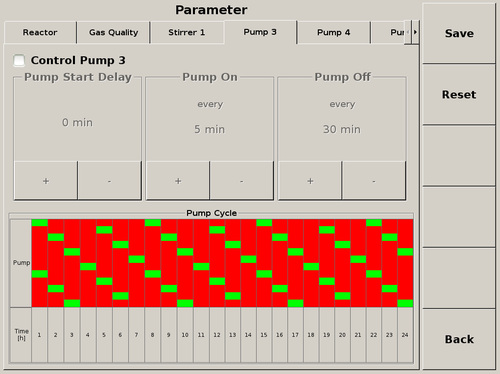

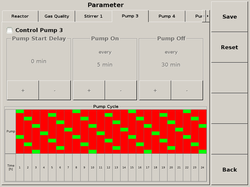

- Asynchronous time control for feeding and discharge

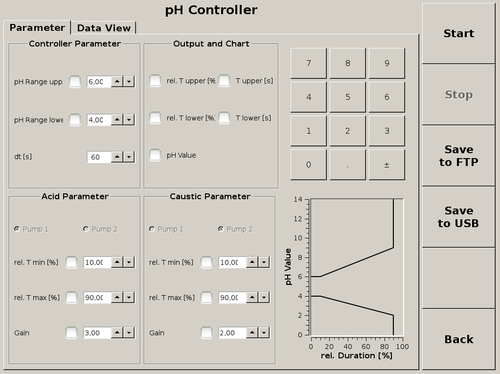

- PID control system for pH-value control

- Basic pump cabinet with doors and individual vessels

- Useable as transfer-pumps for two-stage fermentation tests

Additional Features Eccentric Screw Pumps

- Eccentric screw pumps suitable for larger quantities and particle sizes

- Size of solids content: 6 mm - max. ball passage cross section; other max. sizes of solids on request

- Max. fibre length: 30 mm; other max. fibre on request

- Nominal flow rate: 51 l/h with additional frequency converter for change of the flow rate (minimum 20 l/h)

- External ventilation of frequency converter - necessary for use of minimum range (5 l/h) of the pumps

- Control of pumps via SENSOcontrol

- Asynchronous time control for feeding and discharge

- Monitor of scales

- SENSOcontrol with touch panel

Features Adaption SENSOcontrol

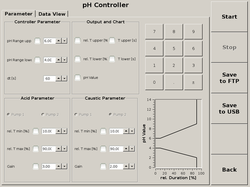

- pH-value control software with the possibility to define the wished pH-value and the control parameters

- Feeding control software with the possibility to define the pumping time and the break time (asynchronous time control)

- Discharge control software with the possibility to define the pumping time and the break time (asynchronous time control)

- Storage of the pumping sequences and visualization

| Bioreactor with measuring technique and stirrer | |

|---|---|

| Dimensions | Vol. approx. 15 liter; OD: 270 mm, wall thickness: 9 mm, height: 350 mm, different volumes on request |

| Material/ Features | Glass cylinder, large discharge and sampling valve on bottom of bioreactor, feeding funnel |

| Measuring technique | pH and temperature sensors, other parameters on request |

| Stirrer | 10 – 500 rpm, max. 600 Ncm |

| Shaft bushing | Gas tight with shaft chamber |

| Heating | Silicon-heater band incl. t-sensor, height of heater band: 200 mm; max. input power for heating: 500 W, adjustment through T-Controller |

| Gas meter / Gas bag | |

| Measuring range | 1…60 l/h; resolution: 2,5 ml |

| Gas bags | Gas bag 1: Volume 5 liters with three-way-valve for storing a retained sample for gas quality determination |

| Gas bag 2: Volume 5 liters with two-way-valve for balance volume during the sampling process | |

| SENSOcontrol | |

| defined pH-value, pumping time and break time (asynchronous time control possible) | |

| Storage and Display unit | pH-value, temperature and gas amount – incl. graphical and tabular display of actual values |

| Control function | Asynchronous timing of the agitator |

| Rack system | |

| Dimensions | 50x50x190 cm |

| Feed and Dischrage Pumps | |

| Tube pump | 0.5 ml/min to 840 ml/min; for feeding, discharge and/or pH-value control; different tube inner diameter; with pump cabinet |

| Eccentric screw pump | nominal flow rate 51 l/h; min. flow rate 5 l/h; max. ball passage cross section 6 mm, max. fibre length 30mm |

Illustrations and descriptions may vary. The plant / product is subject to change depending on technical updates.

We will gladly give you an individual offer.

Anfrageformular

Latest modification: 03.06.2021